Laser marking is a technology for applying images, texts, barcodes to the surface of products. This procedure is used to facilitate product identification. Modern systems can even apply holographic micro-reliefs and hidden codes to the surface of the material, which serve as a defense against product copying.

If you are just looking to buy a laser marking machine, you need to carefully analyse the offerings in the market. One of the leading suppliers of laser marking equipment is Wattsan. They offer a wide range of devices that are characterized by high performance, reliability and versatility. Specialists will help you to choose the optimal solution taking into account the specifics of production and characteristics of processed materials.

Equipment and technologies

The main criterion when choosing marking equipment is the efficiency of laser radiation absorption by the material. For example, for most metals this indicator is in the visible and near-infrared ranges. Laser marking of materials is often used at manufacturing enterprises for quick application of barcodes and other identification information on products. It is used in the following industries:

- Pharmaceutical;

- Automotive;

- food;

- construction;

- chemical;

- cosmetics, etc.

Laser marking offers a number of important advantages over traditional marking methods. It achieves high resolution and accuracy without adversely affecting the physical and operational properties of the material. In addition, laser marking is resistant to external influences and is virtually wear-free, which significantly increases the lifetime of the marking. Another important advantage is the ability to mark even hard-to-reach areas of the product.

Technologies

Lasers with different wavelengths are used to apply identification information to workpieces. The most commonly used lasers for this purpose are fibre, gas, solid state, green and ultraviolet lasers. There are 6 types of laser marking:

- Used for metal processing. Under the influence of high beam temperature, oxidation occurs on the surface of the workpiece, which leads to a change in the colour of its surface. The structure of the metal is not disturbed. The inscriptions are clear and legible.

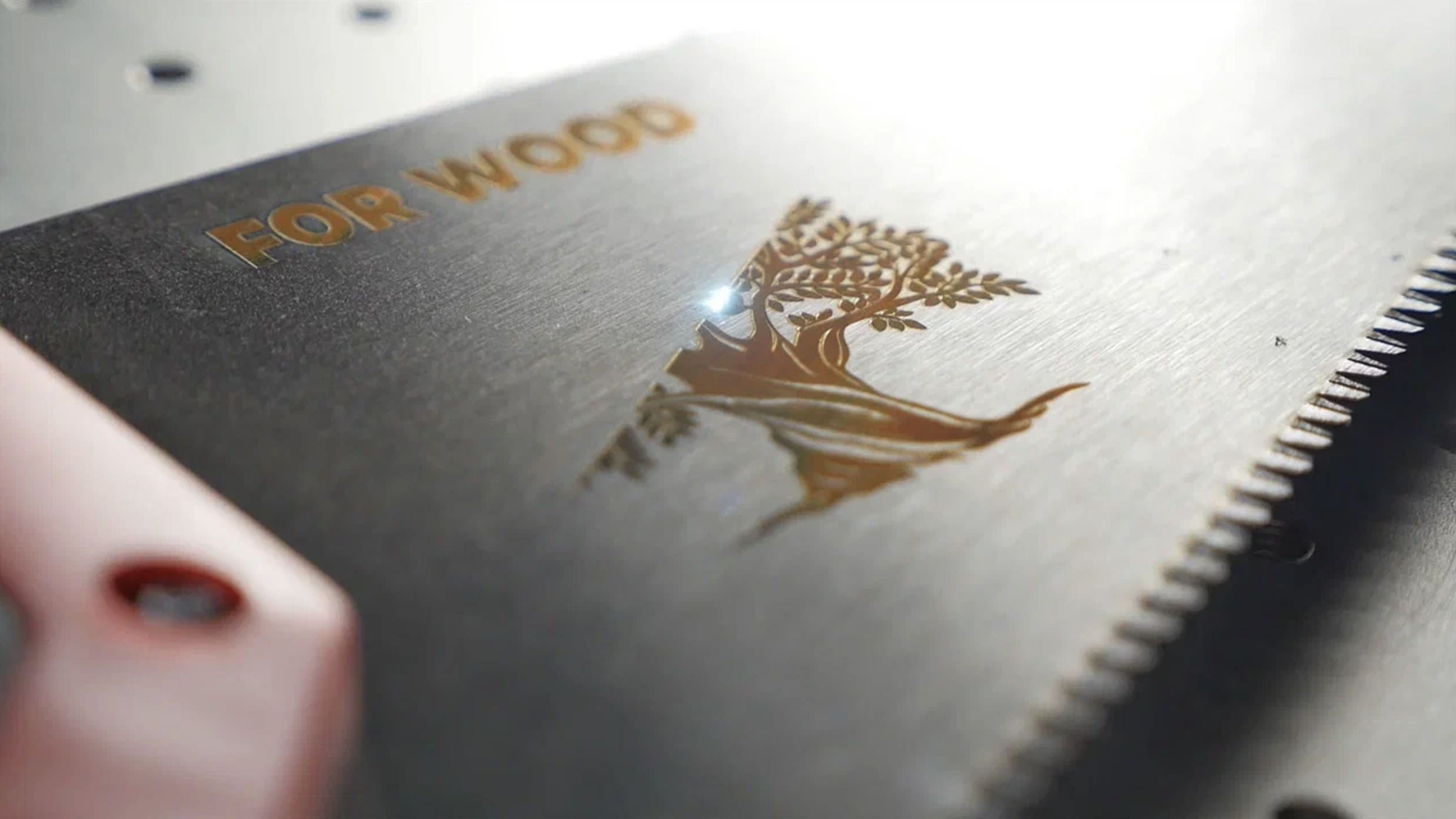

- The surface of the workpiece is melted and vaporised using a laser. The beam also removes part of the material. Notches are formed on the surface, which is called engraving.

- When exposed to heat, a chemical reaction takes place which affects the reflective properties of the surface. Depending on the type of material, the inscriptions take on different colours.

- The beam dissolves the material. As a result, gas bubbles form in the material and scatter the light. As a result, the marked area is brighter than the rest of the unmarked area. This method is mainly used for dark plastics.

Variety of equipment

The devices differ in terms of the type of laser emitters and the technology used. Many laser marking systems are suitable for processing different types of materials. For example, stainless steel, acrylic and wood. The most common types of markers are:

- Based on fibre lasers. The beam is amplified in glass fibre, which increases its intensity. Such devices are used for laser marking of metal, plastic and other materials. Fibre models do not require special care.

- Gas CO2. For the operation of these devices, carbon dioxide is used, which passes into the state of excitation under the influence of electricity. Gas devices are characterised by high power and accuracy. With the correct setting with their help you can mark acrylic, glass, wood, plastic, leather goods, marble.

- Solid-state. The units are equipped with pump diodes. They are characterised by high beam stability, so they are often used in difficult production conditions: under vibration, shaking, strong shocks. With the help of solid-state equipment it is possible to mark metals, plastics, ceramics.

The system can support several types of transmitters. They can be activated by user command or manually connected individually (one transmitter is replaced by another). Some models support simultaneous operation of two lasers.

To ensure the accuracy of workpiece machining, automatic focusing technology is used. This option is provided by ultrasonic sensors. They detect the workpiece, automatically determine the focus point, and then the system moves the work table to the desired position. The operator always has the option of manually adjusting the focus. The user can set the beam coordinates, material thickness. Ultrasonic sensors are usually built into the laser head.

Laser marking is a high-tech and effective way of applying identification information to the surface of various products. It has a number of advantages over traditional methods, such as high accuracy, resistance to external influences and the ability to mark hard-to-reach places. Due to these qualities, laser marking is widely used in various industries, especially where reliable product identification and anti-counterfeiting are required. Further development of laser marking technology will contribute to its wider spread and introduction into new applications.